s farm operations grow in size and complexity so does the importance of good feed management and control. AeroSpreader™ Feed Dispensers provide operators with additional feed delivery rate and dispensing volume information when feeding to biomass charts. The AeroSpreader™ Feed Dispenser may be purchased as part of any new equipment purchase or ordered as an upgrade module for direct in field change out on existing site operating feeders. In either approach a carefully designed and sized feed dispenser module is matched to fit the AeroSpreader™ Model feeder bolting directly in place of the standard Aerite™ annular feed entrainment nozzle assembly.

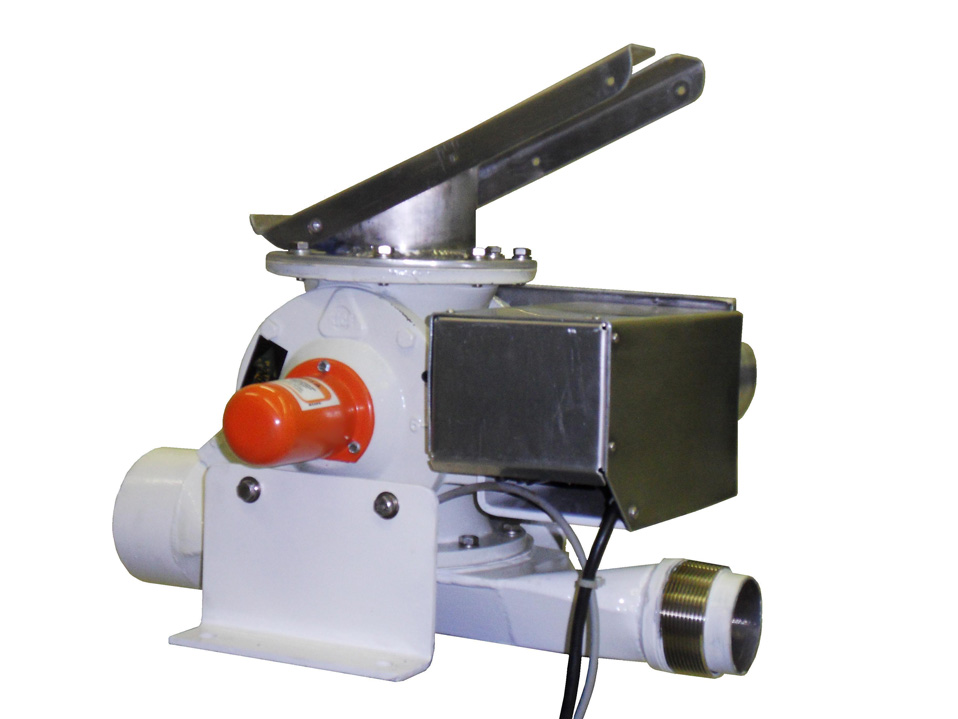

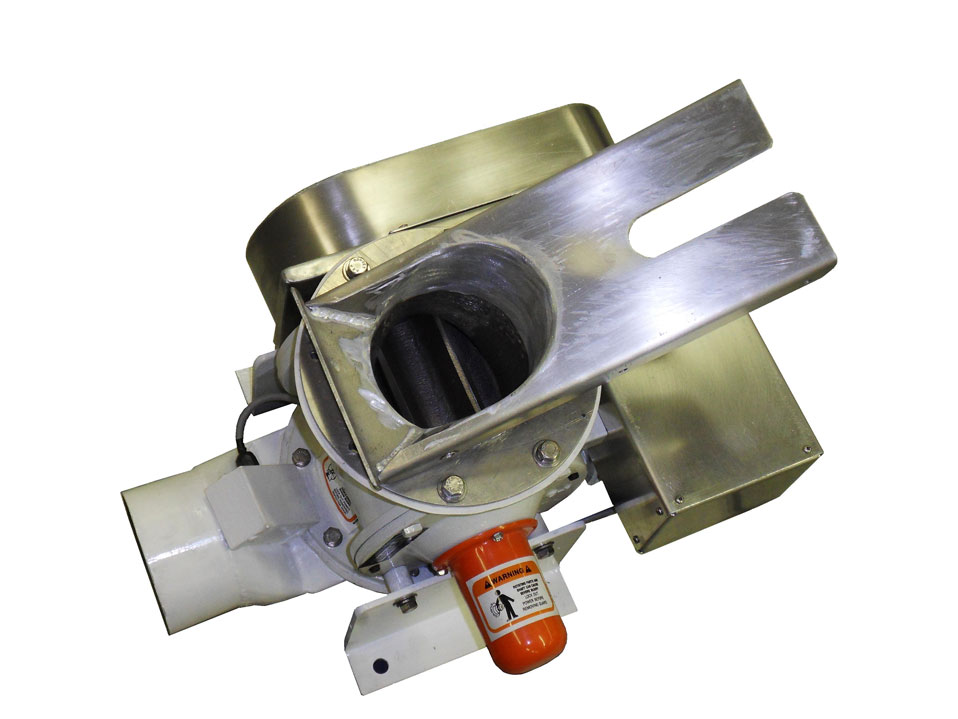

The AeroSpreader™ Feed Dispenser consists of six wedge shaped chambers making up an internal wheel and drive shaft hub that rotates within a cylindrical shaped outer housing. Each of the wedge shaped chambers is gravity loaded from the storage hopper above with a known volume of feed pellets filling each chamber. By monitoring the rotational speed of the drive shaft turning the six-chamber wheel a feed rate and accumulated total amount of feed dispensed can be tracked. The level of feed control can be as simple as operating the rotary valve using a hand adjusted speed control knob to as complex as outfitting the rotary valve with proximity sensors and connecting the system to a FeedMaster™ Controller offering full PLC control of rotary valve operating rates, time durations, and dispensed feed quantities.

The size of the rotary valve housing and the individual wedge shaped chambers within depends upon the model AeroSpreader™ Dry Pellet Feed broadcaster being field retrofitted. Primary focus is to match the largest size rotary valve to the available space beneath the hopper while ensuring change out work is limited to bolting and unbolting component parts. For new AeroSpreader™ product construction there are no physical limitations to the size of the rotary valve housing available other than working to ensuring that during high dispensing speeds the rotary valve has a suitably sized feed pellet storage hopper to draw from.

The AeroSpreader™ Feed Dispenser may be controlled using a simple speed control knob regulating the rotational speed of the rotary valve. Alternatively a slightly more sophisticated control approach incorporates a basic PLC to manage rotary valve speed and time. The ultimate control approach provides full feed dispensing information including feed rate, feed duration, accumulated totals, and alarms for blower speed output and empty hopper.

Ordering a new AeroSpreader™ Dry Pellet Feed Broadcaster or upgrading an in field operating AeroSpreader™ feeder with a rotary valve feed dispenser is also a practical first step to expanding site feed broadcast coverage. While the AeroSpreader™ Feed Dispenser will work admirably well with existing handheld and Periscope Feed Head broadcast systems, the introduction of the rotary valves adds a valuable airlock feature to the feeder. The rotary valve’s design stops any air diverting into the feed hopper and directs all available centrifugal blower generated air down the feed broadcast pipe. This focuses all Aerite™ AB150, AB150E and AB180 model blower generated airflow to move feed pellets along a 18m/60ft length of HDPE pipe to a center cage positioned Aerite™ Feed Spinner. From here additional Aerite™ feed blower modules may be added such as a positive displacement (PD) blower, which offers the higher blower generated air pressure necessary when using even longer HDPE feed delivery pipes found on centralized feed systems. This blower module upgrade is best illustrated when viewing MiniMax™ Centralized Feed Delivery systems.