Farm operations quickly grow in size and complexity and hence, the importance of good feed management and control. We designed our AeroSpreader™ fish food feeder to be upgradable by changing your dispenser module with a larger capacity unit – this is a fraction of the costs of having to replace the entire fish feed dispenser itself.

How to select the right size fish dispenser module?

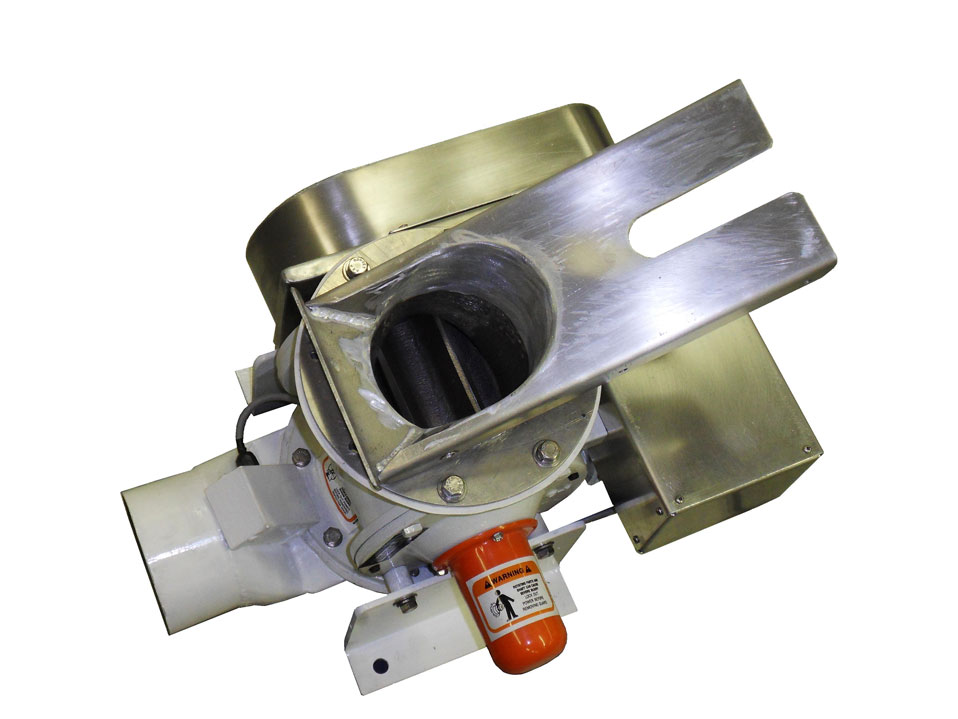

Scaling up your Aerospreader™ performance is as simple as selecting the right size of dispenser module. Depending on the available space below your fish dispenser hopper we recommend maximizing the rotary value size to support a wider range of feed rates and feed pellet types. Selecting the right size feed dispenser module when purchasing a new unit is ideal, but don't worry, we have designed the AeroSpreader™ to have easy bolt on options that can be used to support almost any size fish feed dispensing module you might need.

How do I remotely control and operate my fish food dispenser module?

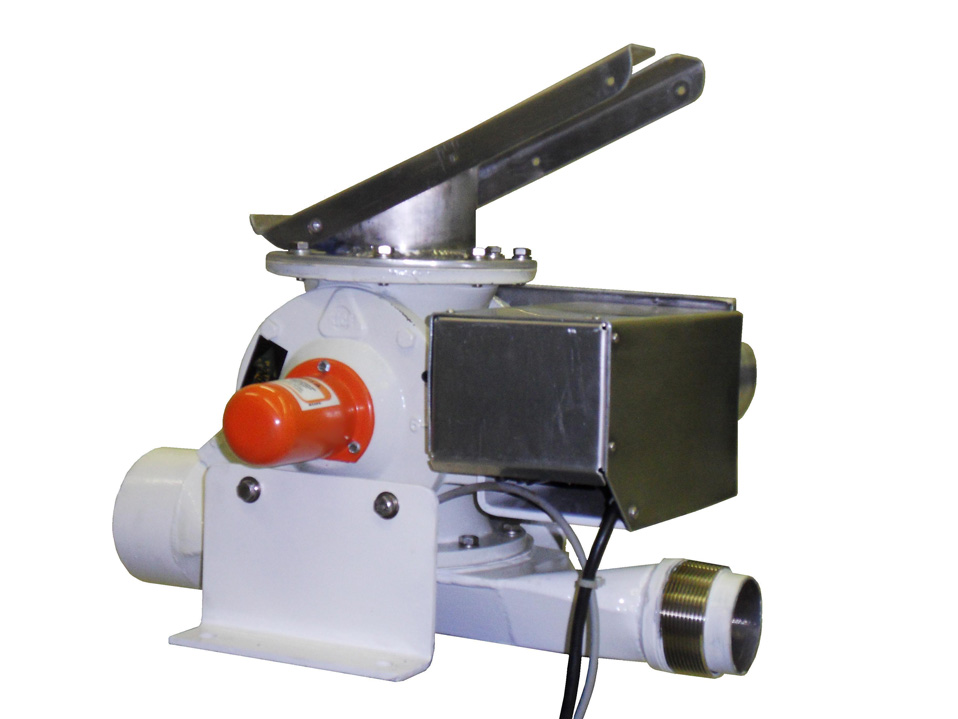

The AeroSpreader™ feed dispenser may be controlled using a simple speed control knob regulating the rotational speed of the rotary valve. Alternatively a slightly more sophisticated control approach incorporates our computerized control module that electronically manages rotary valve speed and time. This approach provides full feed dispensing information including feed rate, feed duration, accumulated totals, and alarms for blower speed output and empty hopper.

Easiiy upgrade your fish dispenser

Ordering a new AeroSpreader™ Dry Pellet Feed Broadcaster or upgrading an in field operating AeroSpreader™ feeder with a rotary valve feed dispenser is also a practical first step to expanding site feed broadcast coverage. While the AeroSpreader™ feed dispenser will work admirably well with existing handheld and Periscope Feed Head broadcast systems, the introduction of the rotary valves adds a valuable airlock feature to the feeder. The rotary valve’s design stops any air diverting into the feed hopper and directs all available centrifugal blower generated air down the feed broadcast pipe. This focuses all Aerite™ AB150, AB150E and AB180 model blower generated airflow to move feed pellets along a 18m/60ft length of HDPE pipe to a center cage positioned Aerite™ Feed Spinner. From here additional Aerite™ feed blower modules may be added such as a positive displacement (PD) blower, which offers the higher blower generated air pressure necessary when using even longer HDPE feed delivery pipes found on centralized feed systems. This blower module upgrade is best illustrated when viewing MiniMax™ Centralized Feed Delivery systems.